Warning: Undefined variable $align in /home4/zelentec/public_html/website_e665a57f/site/assets/cache/FileCompiler/site/assets/cache/HannaCode/images.php on line 20

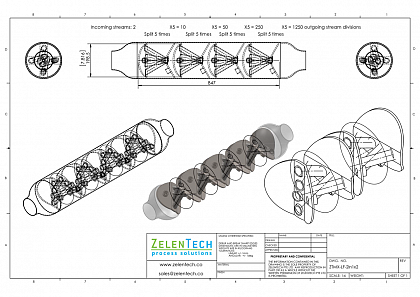

Correctly applied, this design produces a large amount of mixing and extremely small droplet sizes no matter how different the streams to mix are in way of density/viscosity.

Our static mixers are available as fully flanged spool sections or as insert mixer blades to be welded into client pipes. We have made mixers as small as 3/4 inch up to 48 inch in many configurations. We have the capability to make spool sections for low as well as high pressures in a variety of materials.

Our production facility is fully qualified for welding procedures and we can provide anything and everything found in your piping specification. Welding certifications, NDT, customized paint job or whatever it may be.

The ZTMX SRA Mixer can be fitted with injection ports or sampling ports as needed. Sampling Ports will be located in compliance with API8.2 and ISO 3171 to achieve representative samples.

For accurate water content reading we can also incorporate the ZTMX mixer into our ZT-100 Watercut Meter, either as an integral part as for our S ad F-Series, or as a separate spool section suitable for the new I-Series insertion meters.

With the ZelenTech ZTMX you will have no mixed feelings.

"A static mixer is a device for the continuous mixing of fluid materials. Normally the fluids to be mixed are liquid, but static mixers can also be used to mix gas streams, disperse gas into liquid or blend immiscible liquids. The energy needed for mixing comes from a loss in pressure as fluids flow through the static mixer. One design of static mixer is the plate-type mixer and the other device consists of mixer elements contained in a cylindrical (tube) or squared housing. Mixer size can vary from about 6 mm to many meters in diameter. Typical construction materials for static mixer components included stainless steel, polypropylene, Teflon, PVDF, PVC, CPVC and polyacetal."

Wikipedia